A vibratory bowl feeder is one of the popular equipment used in production lines in many manufacturing industries. However, as this is a specialized product, many first-time customers do not understand its functioning. To help with this issue, we decided to provide a blog that exclusively discussed this subject.

The Working of a Vibratory Bowl Feeder

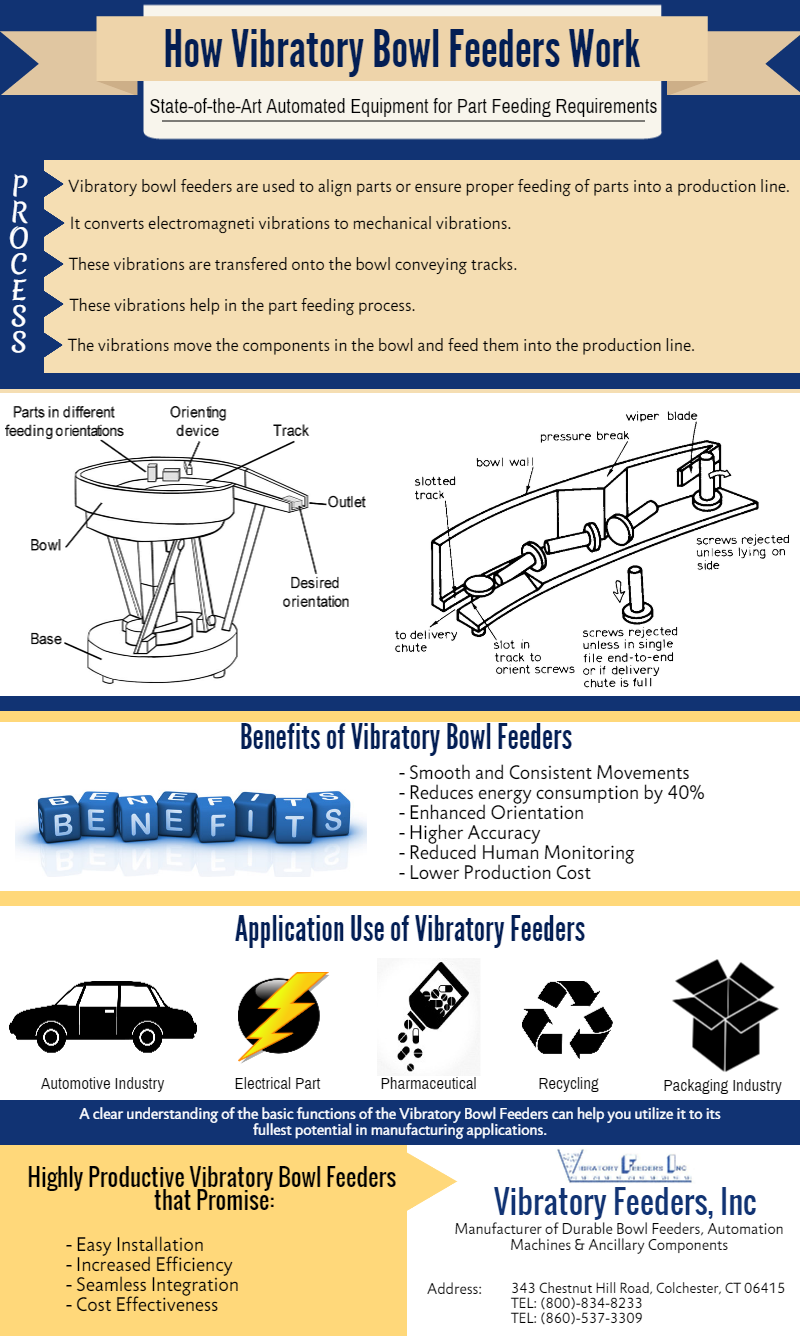

Vibratory bowl feeders are used to align and ensure proper feeding of parts into a production line. The feeder accomplishes this with vibrations, which are created via the use of electromagnets. The electromagnetic vibrations are converted into mechanical vibrations, which help in the parts feeding process.

The bowl is mounted on a base supported by 3 or 4 leaf springs. These restrain the bowl’s movement so that it will only move in a vertical direction. A magnetic coil is fixed below the bowl feeder. Using an external power source, the coil is magnetized, and thus it helps create the electromagnetic vibrations.

Normally, there are anywhere between 1 and 6 electromagnets under the feeder base. Once the magnetic vibrations are converted into mechanical ones, the bowl transfers them onto the bowl conveying tracks. The vibrations move the components in the bowl and feed them into the production line. On an average, the magnet is able to create 100 cycles of vibration frequencies. The vibrations allow the parts in the bowl to either slide or hop along the tracks.

Advantages of the Vibratory Bowl Feeder Operation

As one can imagine, customers and their production lines can benefit immensely from this operation.

- One advantage of this is that there is smooth and consistent movements of the components. Perhaps the biggest advantage of the 100 frequency cycle is that it enables the bowl feeder to reduce its energy consumption by 40%.

- Tooling in the bowl turns the components to the required orientation. This also pushes any misaligned parts to the center of the bowl. The vibrations push the part out and it makes its way back up the track.

A clear understanding of the basic function of the vibratory bowl feeder can help you realize its importance in manufacturing applications.