Cascade Bowls

Cascade bowls are primarily used for feeding easily oriented parts like screws and dowels. They are often quieter and less costly than outside-track designs. Since there are no "over and under" tracks for parts to wedge between, improperly oriented parts are rejected back into the bowl falling only to the lower track.

These bowls can be coated with a variety of materials or welded and polished to meet FDA specifications. They also lend themselves to lining with sheet urethane for wear and noise abatement and with 3M Brushlon for feeding oily parts. All bowls are fabricated from 11-gauge 304 stainless steel and are heli-arc welded.

Tooled bowls are polished on the inside and painted on the outside.

|

|

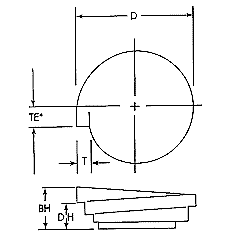

Bowl Diameter D |

Track Width |

Discharge Height |

Bowl Height BH |

Tangent Extension TE* |

Max. Part Length |

Bowl Cap. Cubic In. |

Approx. Bowl Weight Lbs. |

Use |

8 |

1/2 |

2 3/8 |

3 1/8 |

1 1/2 |

3/4 |

30 |

3 |

H-6 |

10 |

5/8 |

2 5/8 |

3 1/2 |

2 |

1 |

45 |

4 |

H-6 |

12 |

3/4 |

3 |

4 1/8 |

2 1/2 |

1 1/4 |

70 |

9 |

H-8 |

15 |

1 |

3 3/4 |

5 |

3 |

1 1/2 |

140 |

13 |

H-10 |

18 |

1-1 1/4 |

3 3/4 |

5 3/8 |

4 |

2-2 1/2 |

160 |

21 |

H-12 |

24 |

1 1/2-2 |

5 |

7 |

5 |

3 1/2-4 |

430-400 |

35 |

C-24 |

27 |

2 1/2 |

5 1/2 |

7 1/4 |

6 |

5 |

600 |

44 |

C-27 |

30 |

2 3/4 |

6 1/4 |

8 |

7 |

6 |

800 |

50 |

C-30 |

36 |

3 |

6 3/4 |

8 1/2 |

8 |

8 |

1200 |

68 |

C-36 |

* Standard Length of tooled feeder.

There are no tangent extensions on blank stainless steel bowls except on special order.