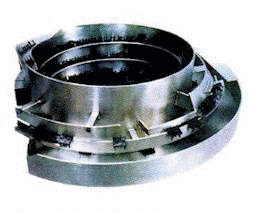

Outside-Track Bowls

Outside-track bowls are used when more intricate tooling is required for proper part orientation, for higher feed rates, or for multiple lines of feed. The outside track is usually pitched downward allowing parts to separate and be more easily oriented. By tooling on the outside instead of the inside, parts tend to buckle and fall into the return pan instead of binding.

|

|

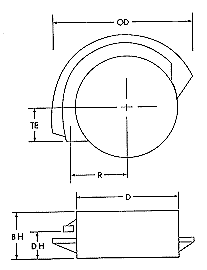

Bowl Core Diam. |

Outside Diam. OD |

Disc. Height Min/Max DH |

Bowl to Discharge R |

Tangent Extension TE |

Bowl Height BH |

Bowl Cap. Cubic In. |

Max. Part Dim. |

Approx. Weight Lbs. |

Use |

6 |

10 |

1 1/2-3 |

4-4 1/2 |

2 |

4-5 |

10 |

1/4 |

10 |

H-6 |

8 |

13 |

1 3/4-4 |

5-6 |

2 3/4 |

4-6 |

20 |

3/8 |

13 |

H-8 |

10 |

16 |

2-5 |

6-7 |

3 1/4 |

4 1/2-7 |

40 |

5/8 |

16 |

H-10 |

12 |

20 |

2 1/2-6 |

7-9 |

4 |

5-8 |

80 |

1 |

22 |

H-12 |

15 |

24 |

3-7 |

9-11 |

5 |

6-9 |

150 |

1 1/2 |

30 |

D-15 |

18 |

28 |

3 1/2-8 |

11-13 |

6 |

8-11 |

275 |

2 |

40 |

D-18 |

21 |

33 |

4-9 |

13-15 |

7 |

9-12 |

400 |

3 |

60 |

D-21 |

24 |

38 |

4 1/2-10 |

15-17 |

8 |

10-14 |

600 |

4 |

85 |

D-24 |

27 |

43 |

4 3/4-11 |

17-19 |

9 |

11-15 |

850 |

5 |

115 |

D-27 |

30 |

48 |

5-12 |

19-21 |

10 |

12-16 |

1200 |

6 |

150 |

D-30 |

36 |

----------Please consult the factory---------- |

||||||||

All bowls are fabricated from 11-gauge 304 stainless steel and are heli-arc welded.