Standard Supply Hoppers to Meet Intrinsic Application Requirements

Vibratory Feeders Inc. is a leading provider of standard supply hoppers and bulk storage hoppers. Our supply hoppers are designed to support part handling systems by providing automatic loading of parts into vibratory bowl feeding systems.

Features and Specifications of VFI Supply Hoppers

We provide seven different types of standard supply hoppers. The models consist of a vibrating tray under the bin. The tray is turned on and off by a paddle switch in the bowl. The feed rate is set by adjusting the door opening in the bin, and the amplitude of the vibrating tray.

Vibratory Feeders Inc. provides standard supply hoppers with the following specifications.

- Capacity Range: 1/2 cu. ft. to 6 cu. ft

- Weight Range: 60 lbs. to 150 lbs

- Depth: 2 1/2 to 15

- Power Supply: 115 or 230 volt or 50 or 60-hertz

- Maximum Amperage: 5 amps at 115 VAC

Advantages of Supply Hoppers

VFI standard supply hoppers can provide a variety of benefits to assorted manufacturing conveyor processes:

- They increase the capacity of the bowl feeder

- A supply hopper eliminates the need to purchase a larger, more expensive bowl feeder

- They control the level of parts in a bowl feeder, thus optimizing the overall efficiency of the feeder

- A vibratory feeder can run for longer periods due to the supply hopper

- Components with unique shapes can be trickle-fed into the feeder with the help of a supply hopper

Points to Remember

There are a few important points that should be kept in mind when choosing a supply hopper for your application.

- The aforementioned weight range is of the supply hopper only. If you choose to add floor pedestals, the overall weight will increase by 120 pounds. The overall weight will further increase if stainless steel is used as the construction material

- Generally, the total weight of parts being fed should not exceed 40 pounds

- You should also keep in mind that the supply hoppers can only support components that are lengths of two feet

If these specifications are not suitable for your application, we can also provide supply hoppers designed to take on heavier parts, or components that get tangled easily.

We at Vibratory Feeders Inc. can supply as well as design supply hoppers to meet your intrinsic manufacturing process requirements. If you would like to know more about our products and services, please feel free to contact us.

|

|

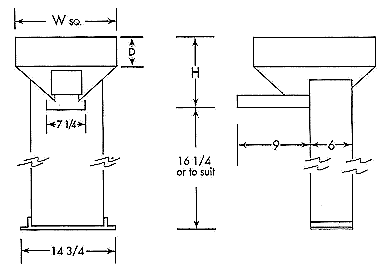

Model Number |

Capacity Cu. Ft. |

Width |

Depth |

Height |

Weight |

HO-1/2 |

1/2 |

15 3/4 |

2 1/2 |

9 |

60 |

HO-1 |

1 |

16 |

6 |

12 1/2 |

85 |

HO-2 |

2 |

18 |

8 |

16 |

100 |

HO-3 |

3 |

24 |

6 |

16 |

115 |

HO-4 |

4 |

24 |

9 |

19 |

125 |

HO-5 |

5 |

24 |

12 |

22 |

140 |

HO-6 |

6 |

24 |

15 |

25 |

150 |

* Add 10-25 pounds for stainless steel

construction and approximately 120 pounds |

|||||

These units run on unrectified current from a 115 or 230 volt, 50 or 60-hertz single-phase power supply. The maximum amperage at 115 VAC is 5 amps.